HCWA Junior Series

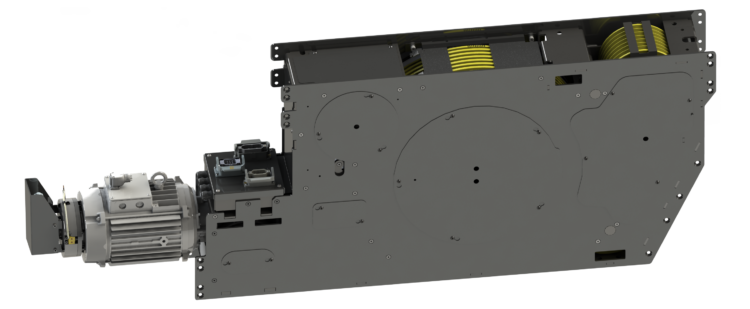

The HCWA JR series impresses with its slim design and its limitless application possibilities. It makes the HCWA JR a perfect choice from regional cultural centres, auditoriums, rehearsal stages, multipurpose halls to opera houses and exhibition halls that are looking to optimize space and efficiency.

The HCWA JR safely moves heavy loads of up to 650 kg with a speed of up to 0,8 m/s and a travel up to 22 m. This Junior hoist comes in a standard in two version one with 5 mm ropes and one with 6 mm ropes.

STANDARD FEATURES & BENEFITS

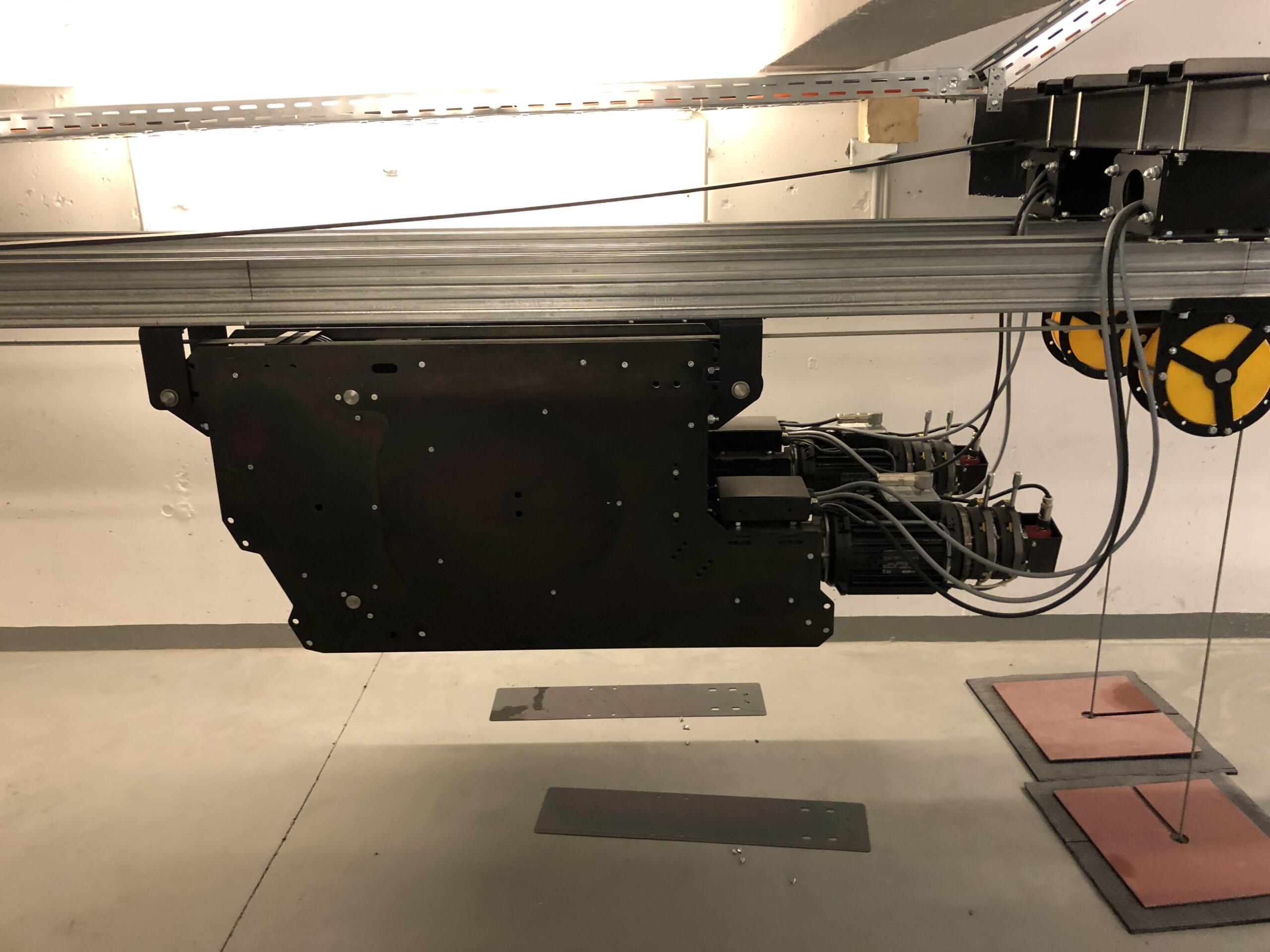

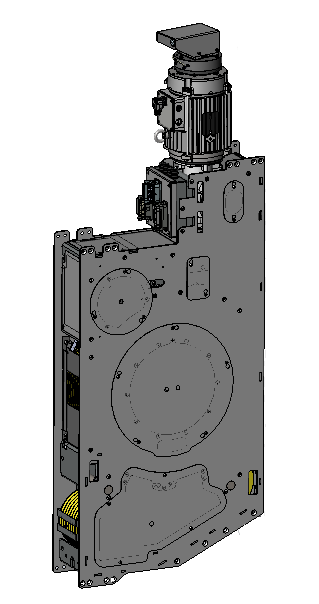

- Extreme compact construction of less than 200 mm, also qualifies the hoist for replacing existing manual counterweight systems in theatres

- Zero fleet hoist. No interfering rope angles.

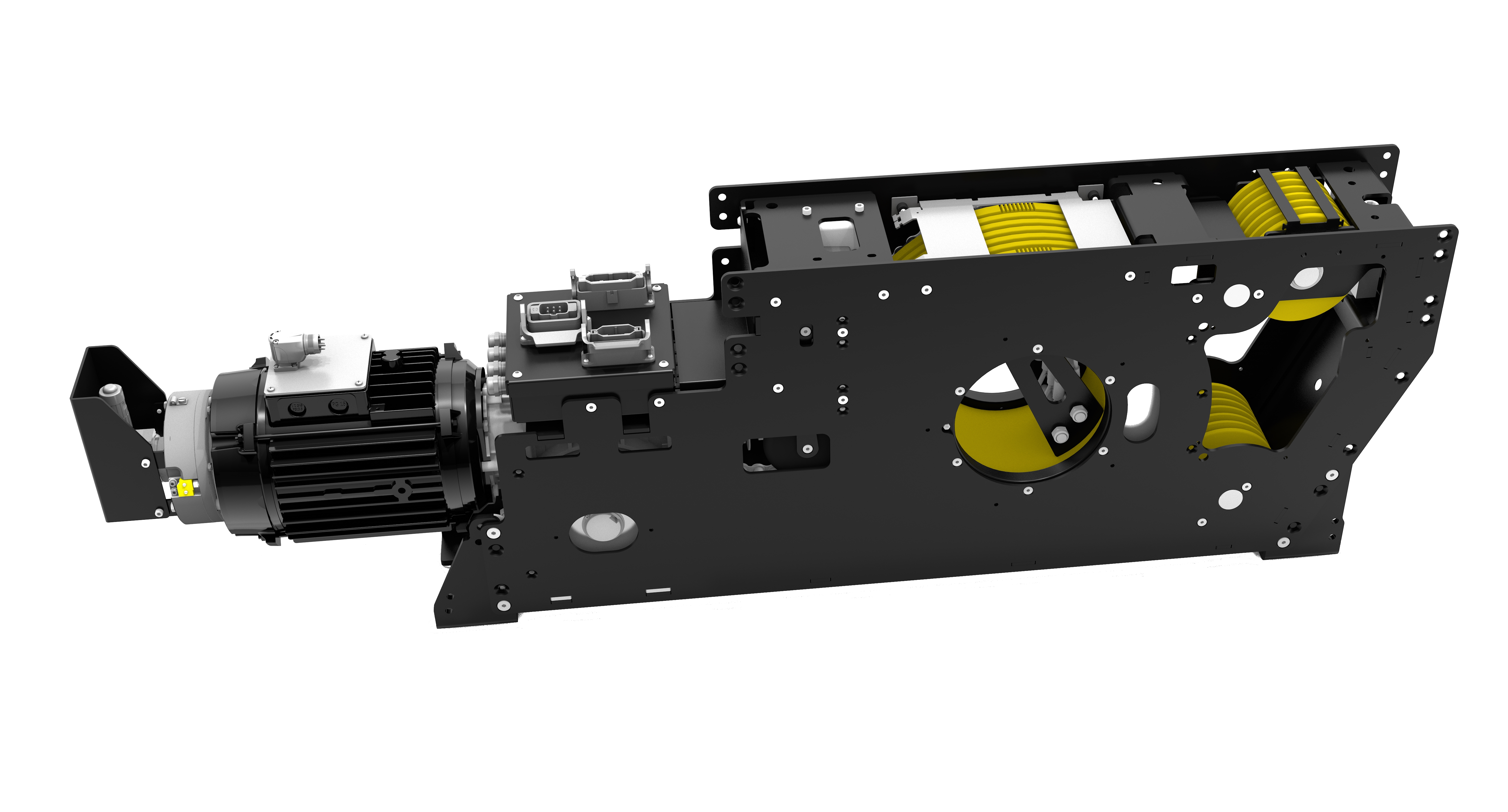

- Redundant drum drive with two individual chains.

- Special chain tensioning system for quiet operation.

- The hoist features gearboxes with a safety catch, which sets a superior safety standard in the market.

- Pile wind drum inside of a particularly high-quality cast polyamide drum.

- The steel frame inside the cast polyamide drum prevents drum collapse in event of a fire.

- Extremely silent and smooth-running of ropes due to cast polyamide drum is ensured (long life expectancy)

- The standard drum consists of 6 or 7 grooves (more grooves on request). In case of less, the grooves will be filled up by ASM and can always be reopened later.

- Ropes are inserted and crimped inside the steel frame of the drum and securely fixed with quick links in the steel drum housing. This attachment of the ropes ensures full safety without extra safety turns (according to EN 17206)

- Rope pulleys and rope drum are yellow according to German regulations (black ones available on request)

- Depending on the machine type, the encoders are arranged directly on the rope drum via a toothed wheel or directly on the motor shaft and gearbox shaft.

- The side covers are available in metal or on request with magnetic shields for easy access during maintenance.

THE HCWA JUNIOR RANGE

The HCWA JR models with speed 0,1 & 0,2 m/s are equipped as standard with a dynamic self-locking gear and an extra safety catch integrated in the gearbox. The equipment with a dynamic self-locking gear allows the operation without brakes. It ensures a smooth deceleration of the load even in the event of a power failure. Since brakes are not required, the hoist requires less maintenance.

The control possibilities reach from a 24V, third party control to a full synchronous ASM GENESIS SIL3 control.

The HCWA JR models with speed 0,8 m/s are equipped as standard with an extra safety catch integrated in the gearbox and two silent theatre brakes.

The hoist allows the highest available performance for scenic applications, which means operating in high speed while positioning exactly.

The control possibilities allow a full synchronous group drive with ASM GENESIS SIL3 control or a third-party control.

The standard HCWA JR 400 is equipped with a drum consists of 6 grooves with 5 mm ropes.

The standard HCWA JR 600 is equipped with a standard drum consists of 7 grooves with 6 mm ropes.

If less ropes are needed, ASM or the approved partner will close the extra grooves professionally.

If more ropes are needed optional extra grooves are possible (Beware that the total width of hoist will be more than 200 mm).

The HCWA JR models can be delivered with a compression profile to simplify the mounting on site.

HCWA JR |

|||||||

|---|---|---|---|---|---|---|---|

JR 400 |

JR 600 |

||||||

| Max (variable) speed in m/s | 0,1 | 0,2 | 0,8 | 0,1 | 0,2 | 0,8 | |

| Hoist capacity in kg on ropes | 650 | ||||||

| Number of ropes (standard)* | 6 | 7 | |||||

| Load bearing line | rope, 5 mm | rope, 6 mm | |||||

| Max travel in m | 11,5 | 22 | |||||

| Safety system | self-locking gear | two brakes | self-locking gear | two brakes | |||

| Motor performance in kW | 1,5 | 4 | 5,5 | 1,5 | 4 | 5,5 | |

*different number of ropes on request.

As ASM engineered each hoist to their fullest capacity, each model has their specific composition which cannot be altered. Special models can be offered on request.

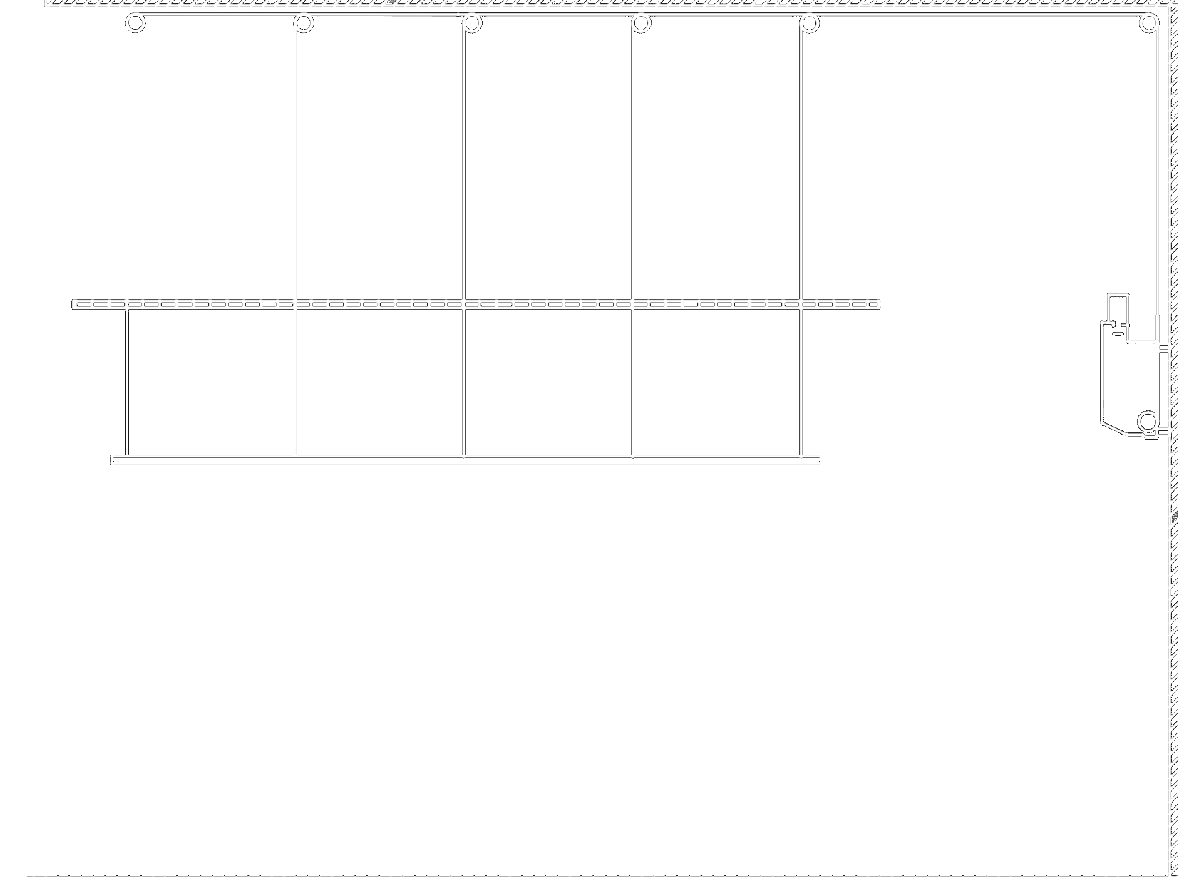

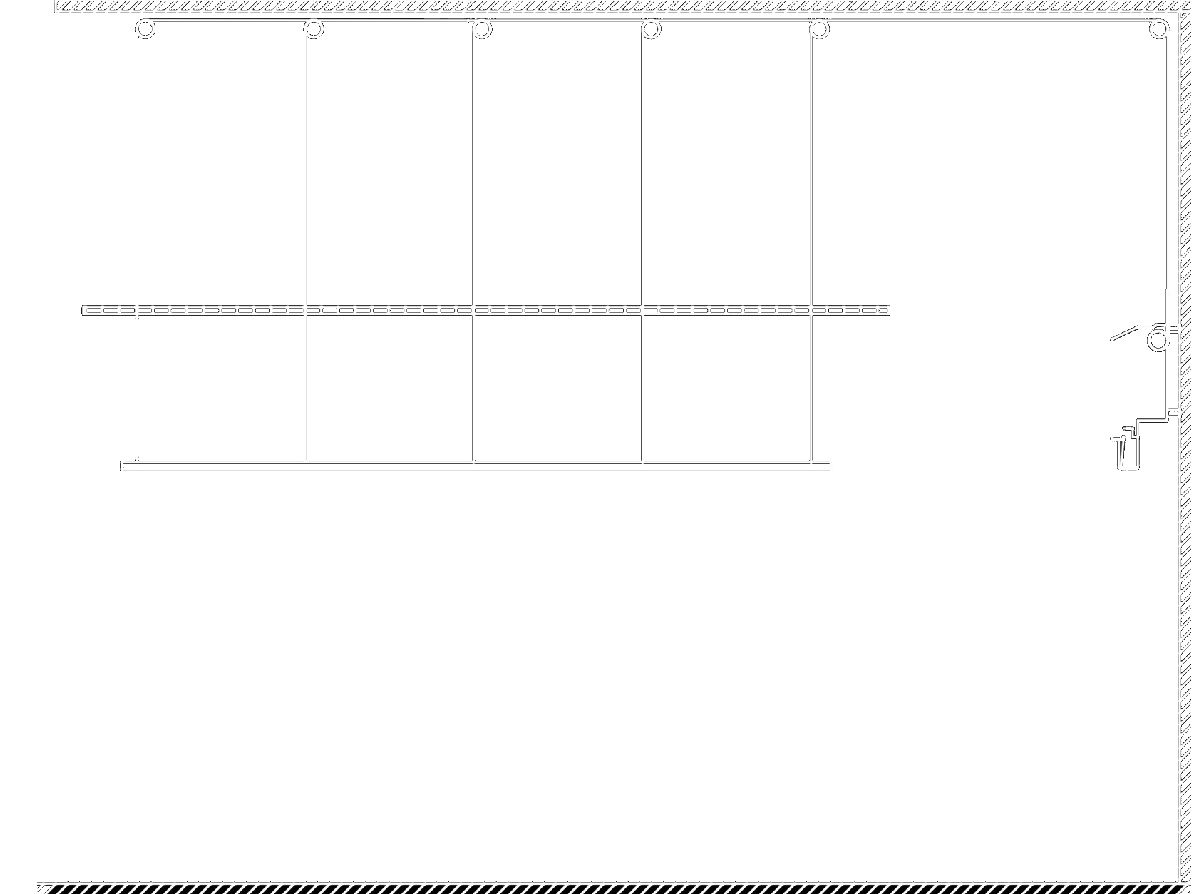

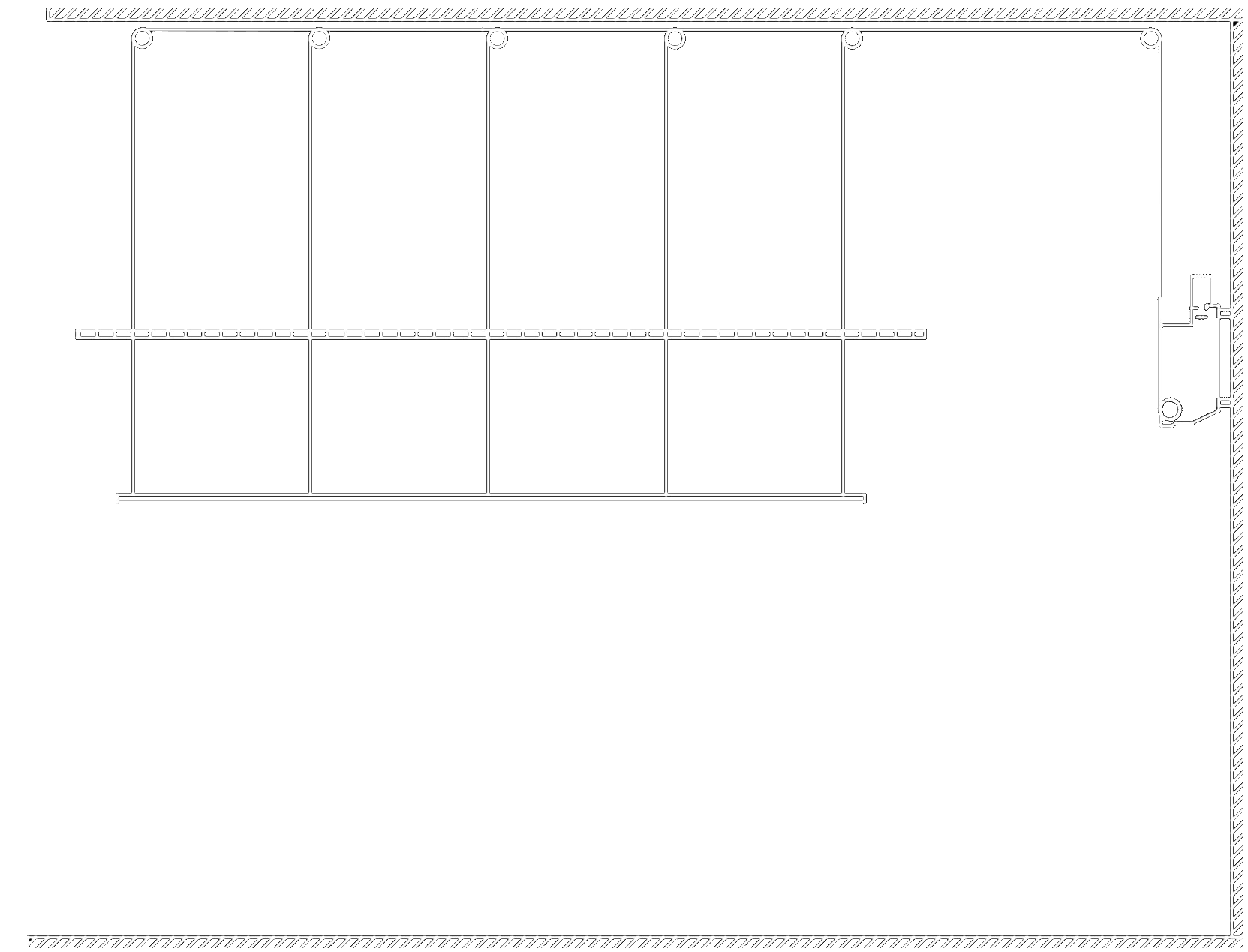

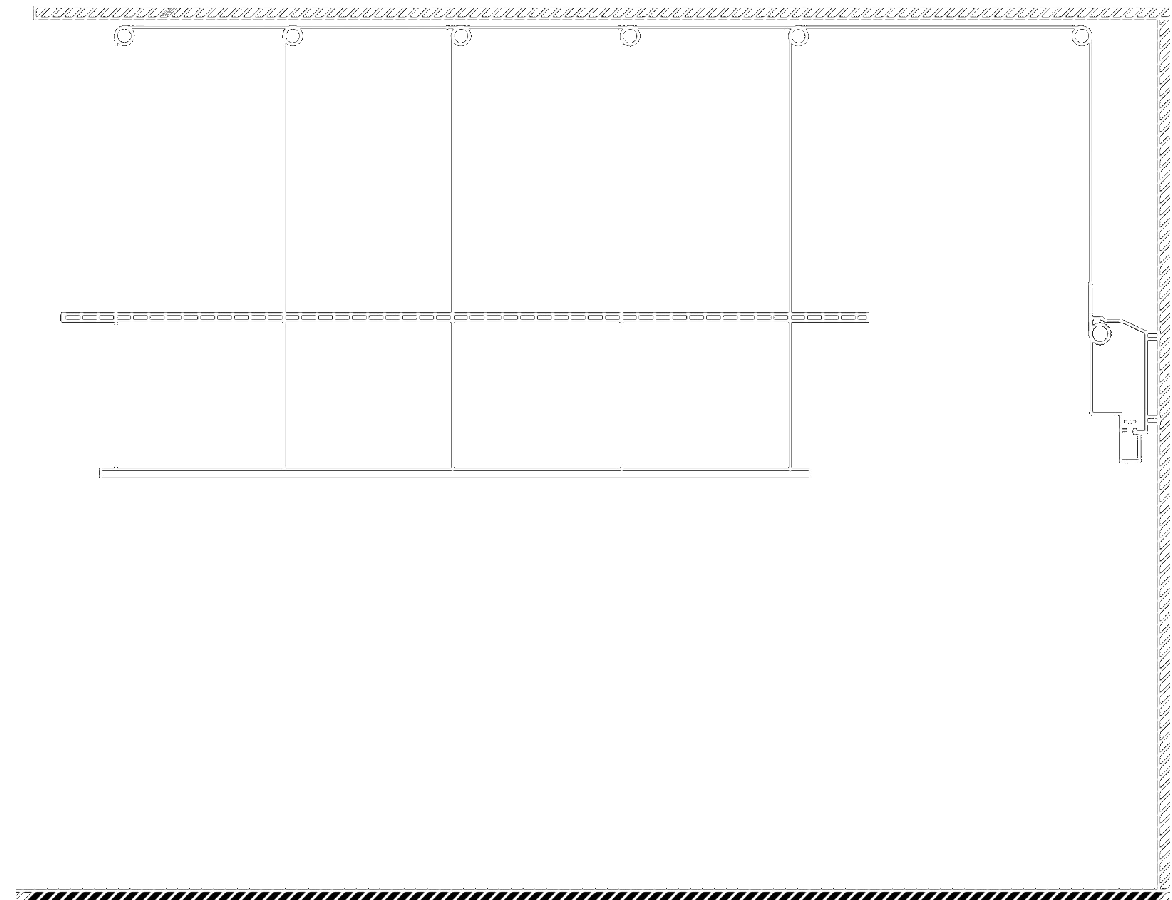

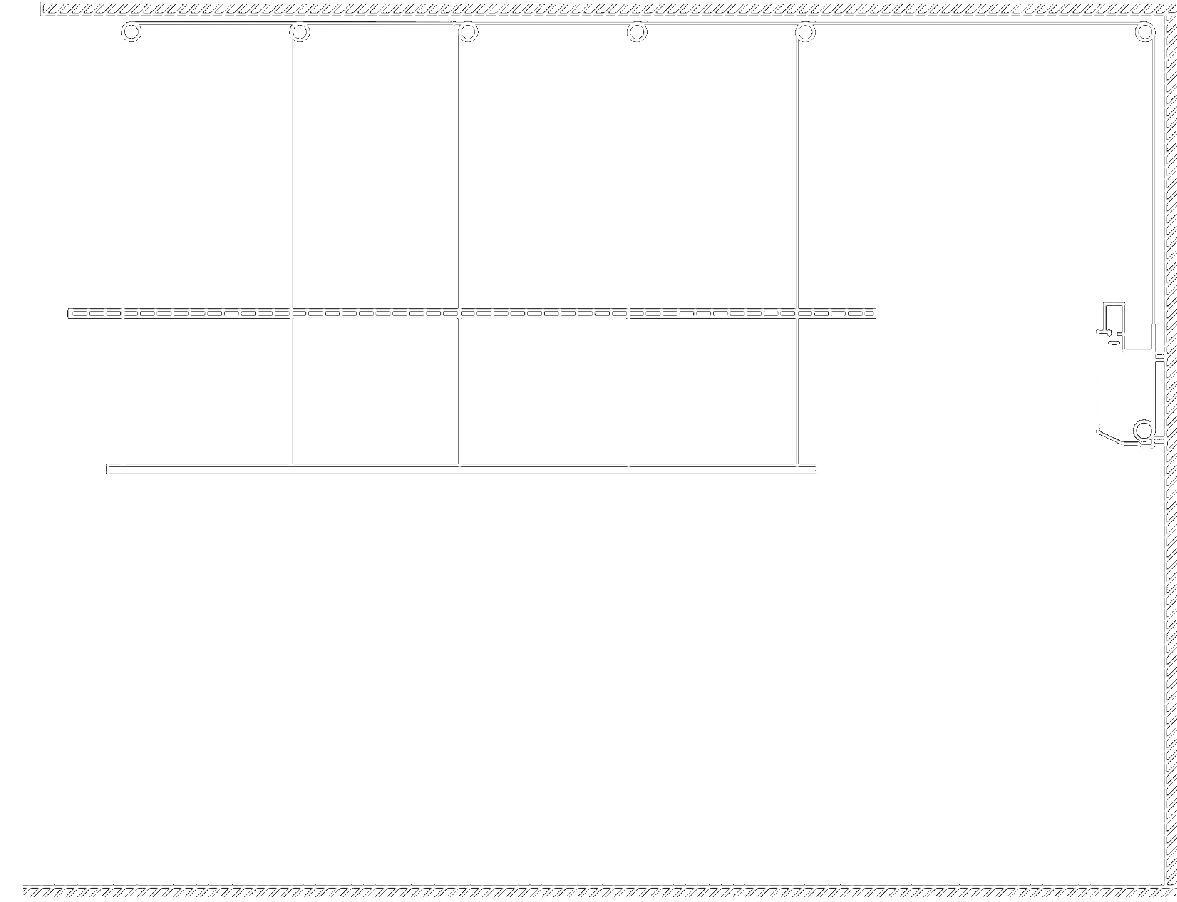

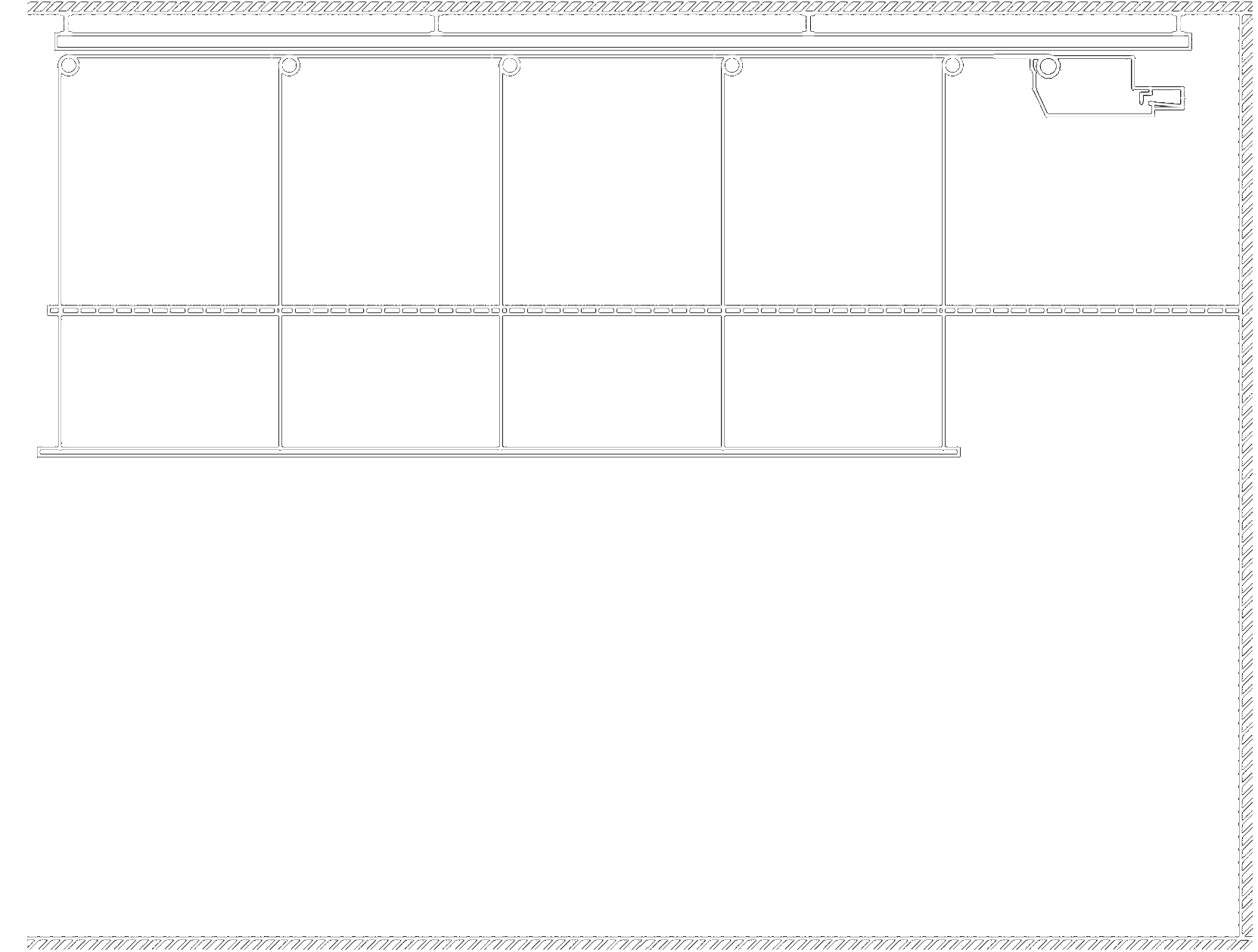

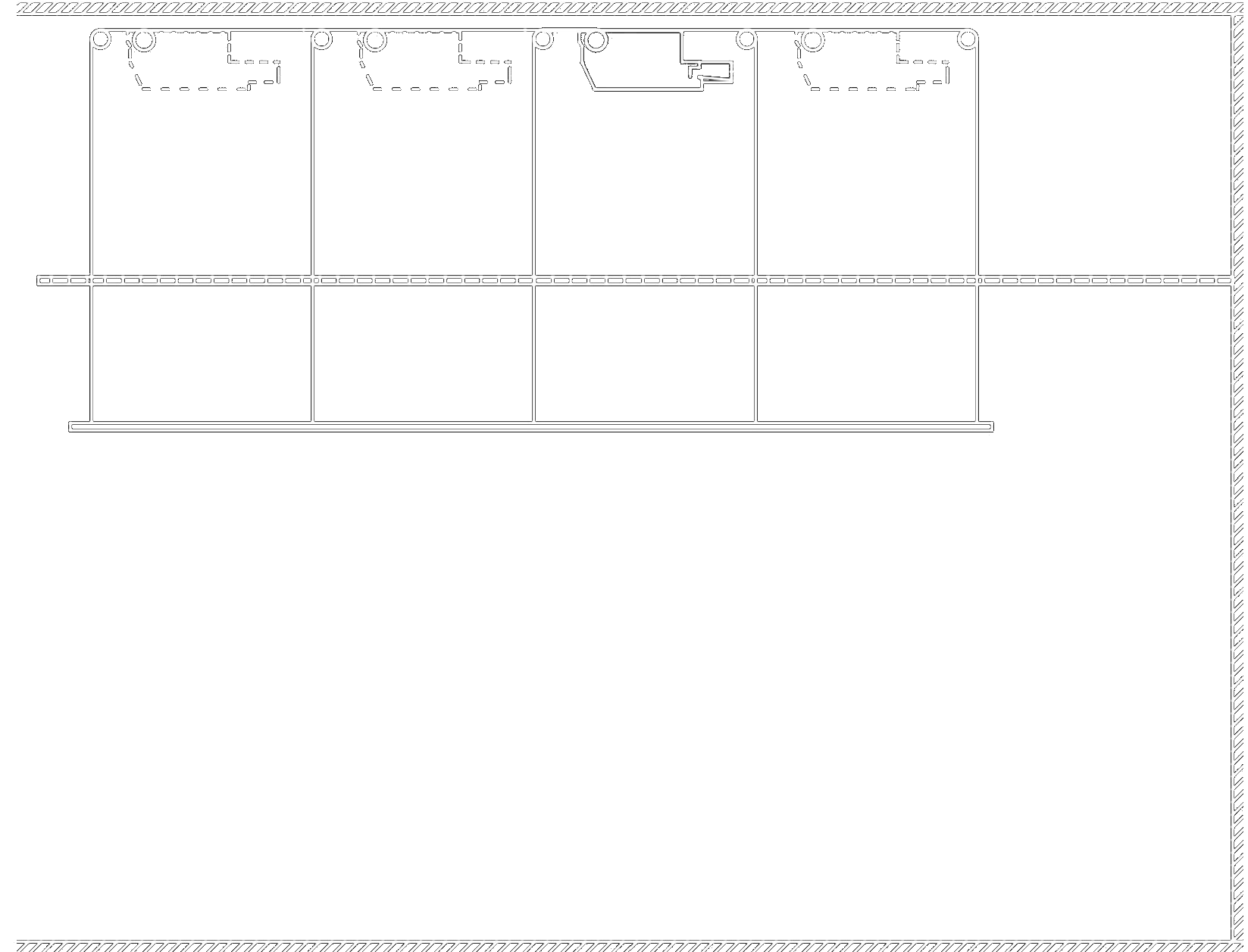

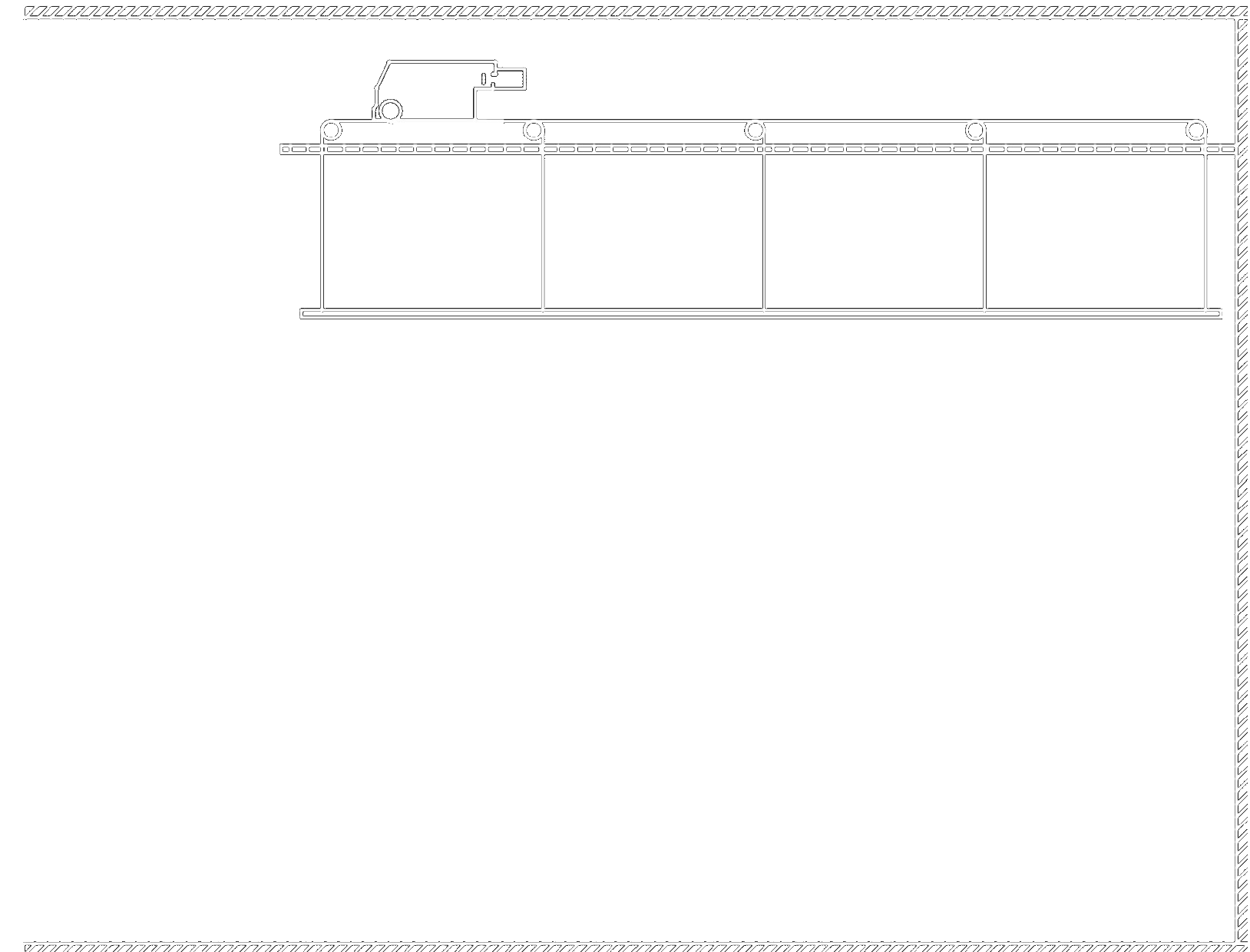

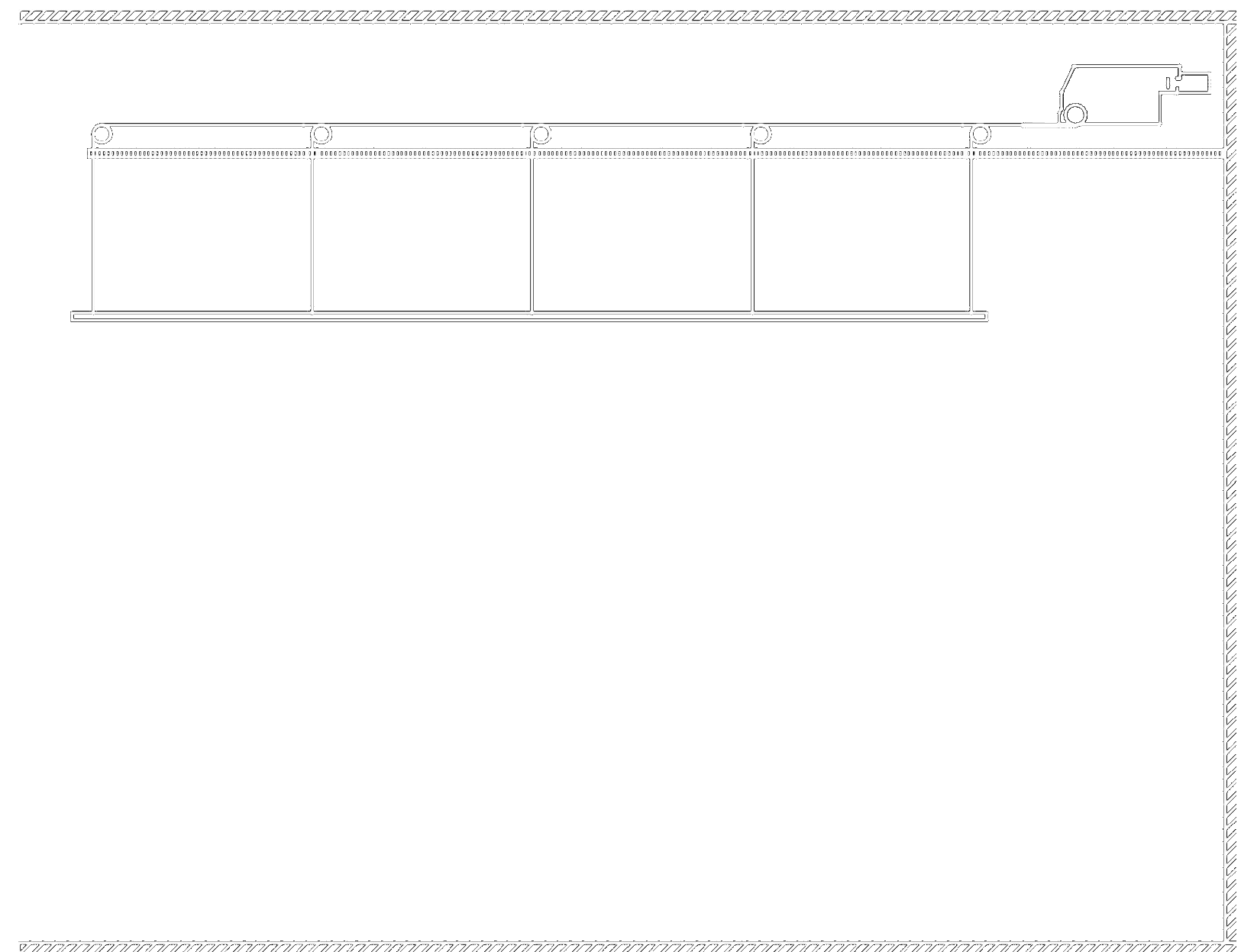

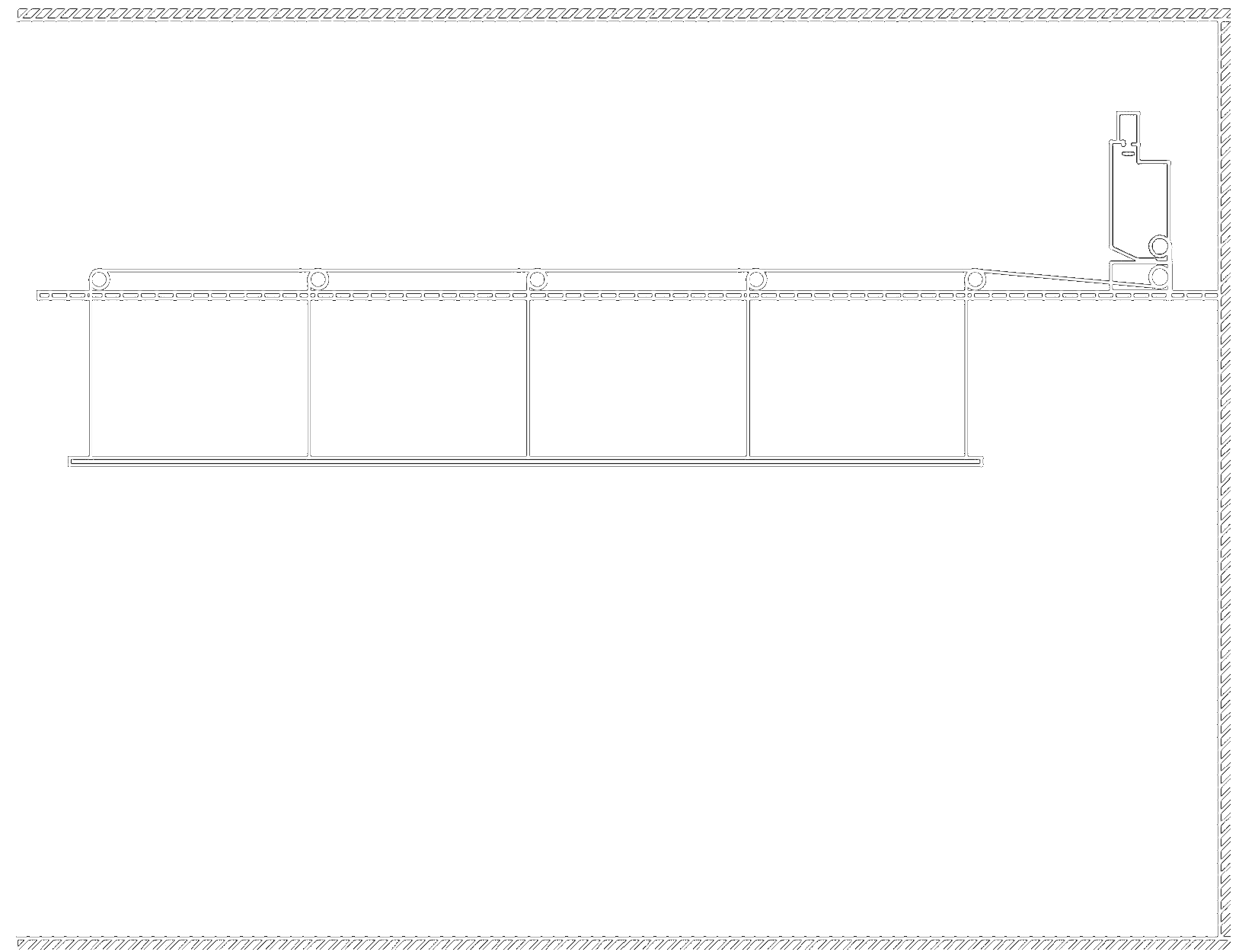

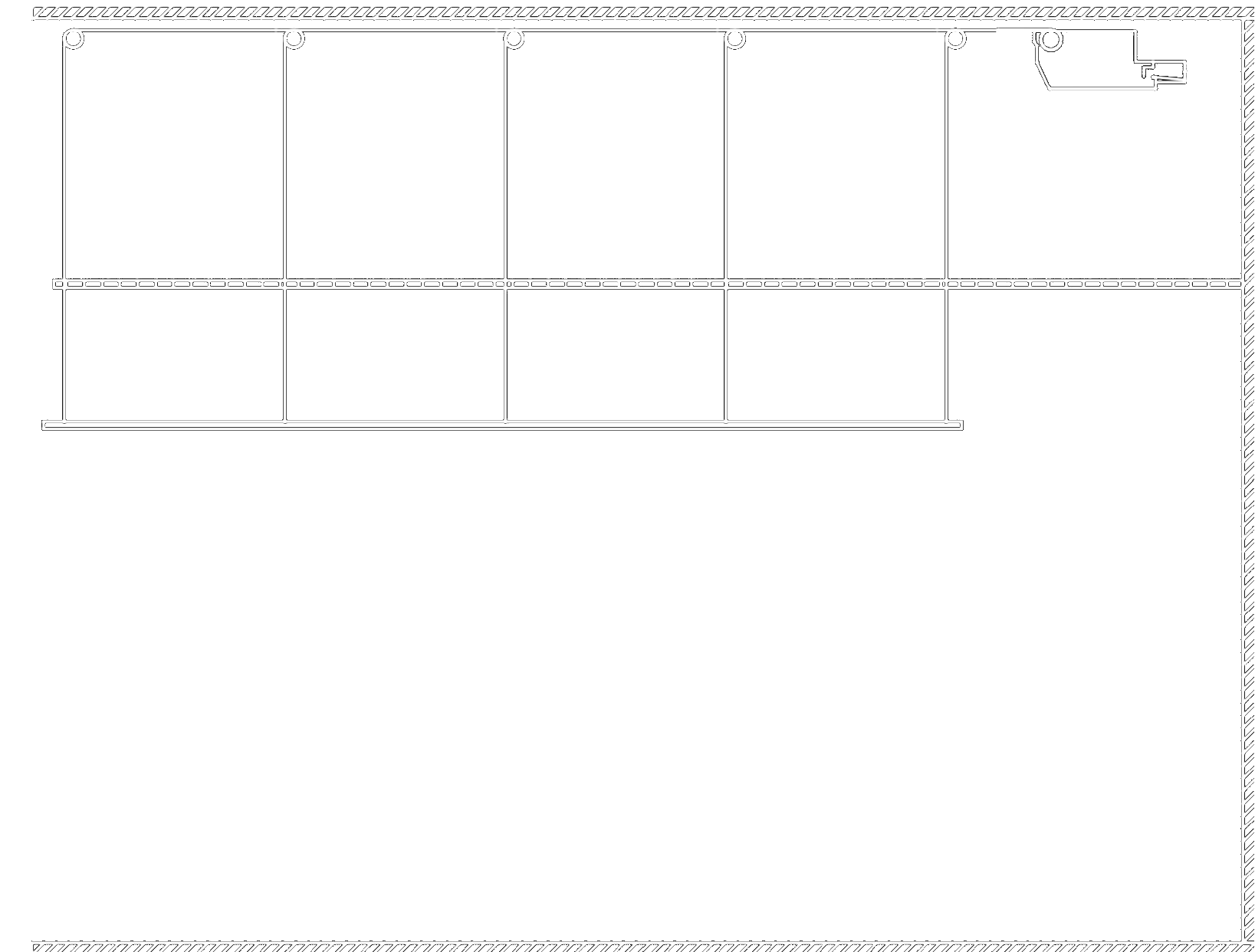

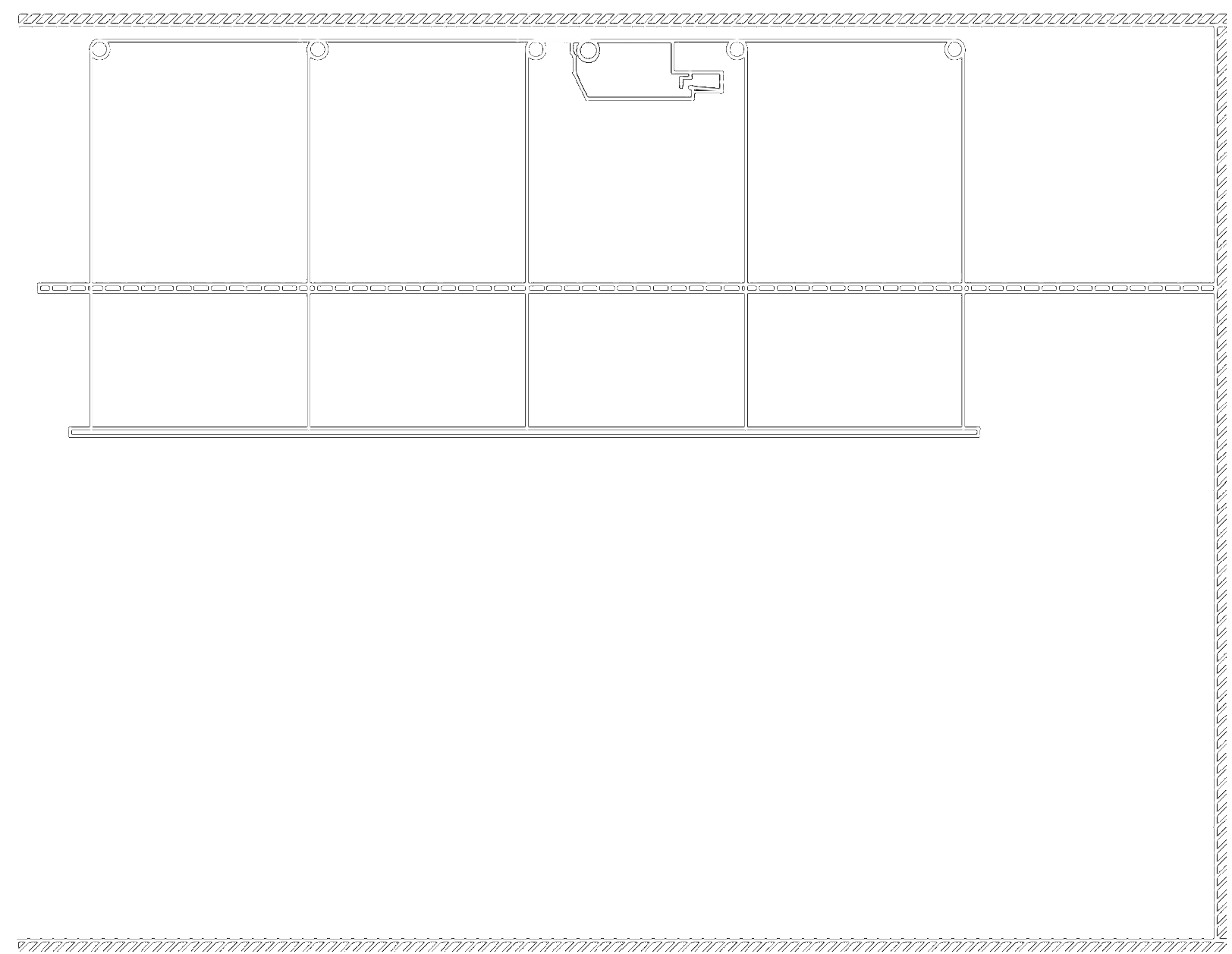

The HCWA JR hoist is designed for various installations positions. The rope pulley exits are variable as required.

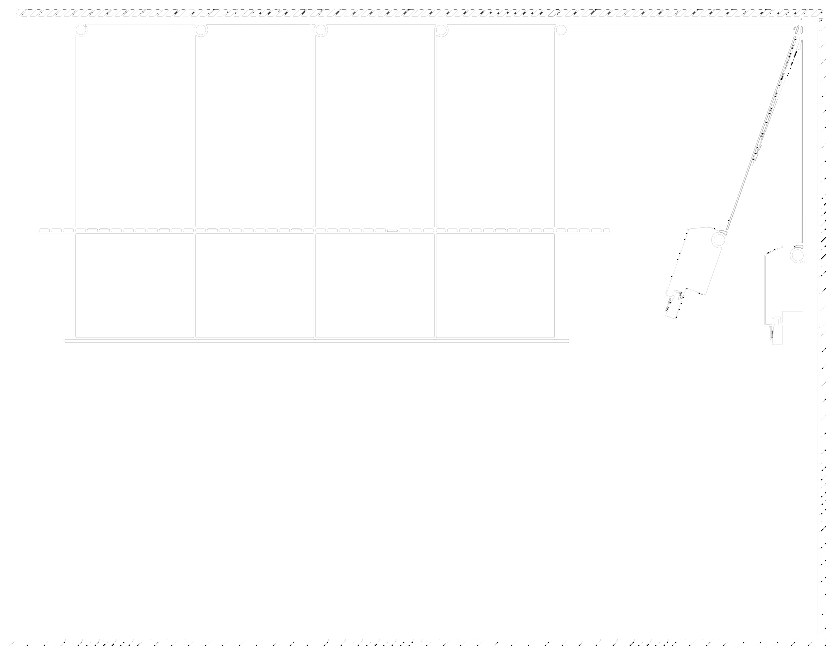

METHODS OF INSTALLATION